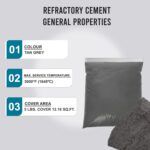

Simond Store Refractory Cement 5 Pound – High Temperature (3000F) Rated – Refractory Coating for Ceramic Fiber Insulation in Blacksmithing Forge, Kiln, Smelting Furnace

$21.99 $26.99

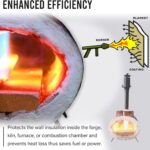

- Applications: Highly effective as a fire refractory coating for ceramic fiber insulation in the gas forge, ceramic kilns, inductions, furnaces, foundries, etc.

- Durability: Our heat refractory cement makes a thick and durable layer on the ceramic fiber insulation. It resists your potential propane heat and withstand working temperatures up to 3000F

- Easy to Apply: This heat resistant coating is too easy to apply, just mix with water and blend it for 8 to 10 minutes to avoid air bubbles, apply it on a ceramic fiber blanket in a blacksmith forge, ceramic kiln, or foundry, furnace, and let it dry

- Enhanced Efficiency: This refractory coating for ceramic fiber protects the wall insulation inside the kilns, furnaces, or combustion chamber and prevents heat loss thus saves fuel or power

- Material: This refractory cement is a combination of small particles and components of alumina and silica which reflect radiant heat into the foundries, kilns, or furnaces to maintain the efficiency of the temperature

Only 25 left in stock - order soon.

Description

Product information

| Product Dimensions | 13 x 7 x 3 inches |

| ASIN | B0C2KD9NZX |

| Customer Reviews | 4.5 out of 5 stars |

| Best Sellers Rank | #549,198 in Arts, Crafts & Sewing #418 in Firing Accessories |

| Item Weight | 5 pounds |

| Manufacturer | Spectra Overseas |

| Date First Available | April 15, 2023 |

Be the first to review “Simond Store Refractory Cement 5 Pound – High Temperature (3000F) Rated – Refractory Coating for Ceramic Fiber Insulation in Blacksmithing Forge, Kiln, Smelting Furnace”

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.